O-ring Squeeze Calculator

Using the O-ring Squeeze Calculator:

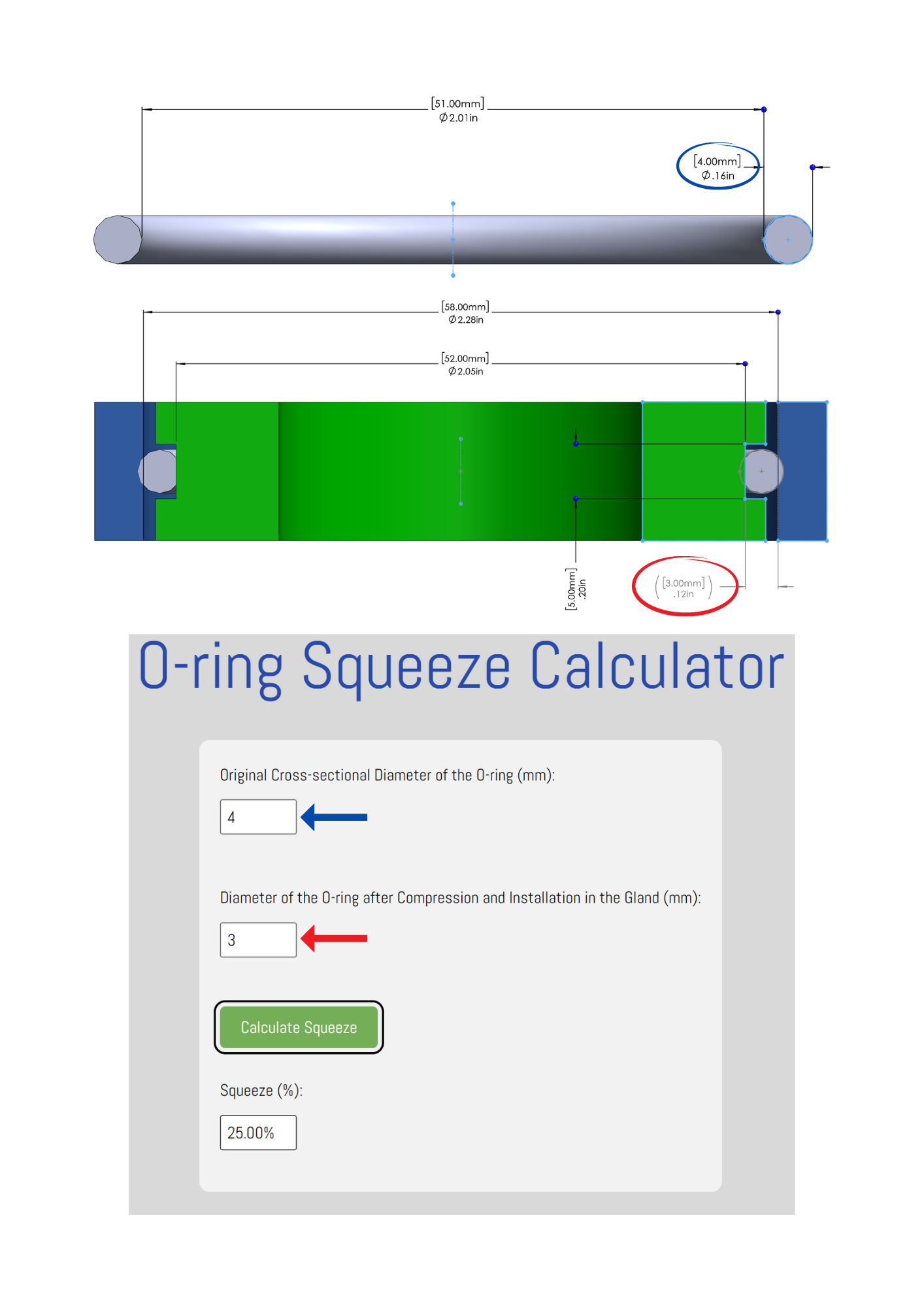

Input the original cross-sectional diameter of the O-ring in millimeters or inches in the first field.

In the second field, enter the diameter of the O-ring after it has been installed in the gland and compressed to create a seal. This diameter represents the size of the O-ring after compression, and it does not take into account its size before installation or the size of the gland.

Click the "Calculate Squeeze" button to obtain the squeeze percentage, which will be displayed in the read-only field labeled "Squeeze (%).”

Notes:

Please note that the original cross-sectional diameter must be greater than the diameter after compression and installation in the gland. If this condition is not met, an error message will be displayed.

The squeeze percentage indicates the amount of compression that the O-ring underwent during installation, expressed as a percentage of its original cross-sectional diameter.

You must use either millimeters or inches consistently for both the original cross-sectional diameter and the diameter after compression and installation in the gland. Mixing units is not allowed.

The O-ring Squeeze Calculator is a tool to help estimate the amount of compression that an O-ring has undergone during installation. The results should be used for reference purposes only and are not a guarantee of the actual squeeze percentage.

Overview of O-rings and their applications

When designing and installing O-rings in industrial machinery, it is important to consider the recommended squeeze ranges for both static and dynamic applications. These ranges help to ensure that the O-ring provides an effective seal while also avoiding over-compression, which can cause the O-ring to deform and lose its sealing ability.

For static applications, a squeeze range of 5-10% is typically recommended. In dynamic applications, the recommended squeeze range is typically 10-20%. The exact squeeze range will depend on various factors such as the size and shape of the O-ring, the materials used in the O-ring and gland, and the operating conditions such as temperature and pressure.

Our O-ring squeeze calculator can assist in determining the squeeze percentage experienced by the O-ring during installation. By inputting the original cross-sectional diameter of the O-ring and the diameter after compression and installation in the gland, the calculator will provide the squeeze percentage. This information can be used to determine whether the squeeze experienced by the O-ring falls within the recommended range for its specific application, helping to ensure optimal O-ring performance.

It is important to note that the squeeze calculator is just one tool that can be used in the design and installation process. Other factors such as temperature, pressure, and the materials used in the O-ring and gland can also affect the squeeze and overall performance of the O-ring. As such, the squeeze calculator should be used in conjunction with other design and testing processes to ensure optimal O-ring performance.

Importance of O-ring squeeze

There are several factors that can influence the amount of squeeze experienced by an O-ring during installation. Some of the most significant factors include:

Temperature: Changes in temperature can cause O-rings to expand or contract, affecting the amount of squeeze experienced during installation.

Pressure: The pressure applied to the O-ring during installation can also affect the amount of squeeze experienced. Higher pressure will result in greater squeeze, while lower pressure will result in less squeeze.

Materials: The materials used in the O-ring and gland can also affect the amount of squeeze experienced by the O-ring. Different materials have different compression and expansion rates, which can impact the amount of squeeze experienced during installation.

By understanding these factors, engineers and technicians can take steps to optimize the design and installation of O-rings in industrial machinery, ensuring reliable sealing performance. It is important to note that while the O-ring squeeze calculator can provide valuable insights into the squeeze experienced by the O-ring, it should be used in conjunction with other design and testing processes to ensure optimal O-ring performance.

Factors affecting O-ring squeeze

Temperature can have a significant impact on the squeeze of an O-ring, as changes in temperature can affect the elasticity and resilience of the O-ring material. In general, as temperature increases, the O-ring will become more flexible and pliable, resulting in increased squeeze during installation. Conversely, as temperature decreases, the O-ring will become stiffer and less pliable, leading to decreased squeeze.

It is important to consider the temperature range that the O-ring will be exposed to in its application, and to select an O-ring material that is suitable for these conditions. For example, some O-ring materials may become brittle at low temperatures, while others may degrade or lose their elasticity at high temperatures.

In addition to selecting an appropriate O-ring material, engineers and technicians can also use temperature compensation techniques to adjust the squeeze of the O-ring based on temperature changes. These techniques can help to ensure that the O-ring provides a consistent and reliable seal over its operating temperature range.

By considering the impact of temperature on O-ring squeeze and taking appropriate steps to address it, engineers and technicians can help to ensure that the O-ring provides effective and reliable sealing performance in their applications.

Materials used in O-rings and their impact on squeeze

O-rings are commonly made from a variety of materials, each with their own unique properties and characteristics that can impact the squeeze experienced during installation. Some common materials used in O-rings include nitrile rubber, silicone, fluorocarbons, and polyurethane.

Each material has its own unique set of properties, such as temperature and chemical resistance, which can affect the squeeze experienced by the O-ring during installation. For example, some materials, such as nitrile rubber, are known for their strong resistance to temperature and chemicals, making them ideal for use in harsh industrial environments. However, these materials may be more rigid and less flexible than other materials, which can result in increased squeeze during installation.

On the other hand, materials such as silicone are known for their flexibility, which can help to reduce the squeeze experienced by the O-ring during installation. However, these materials may not be as resistant to temperature and chemicals as other materials, making them less suitable for use in harsh industrial environments.

It is important to consider the properties of the O-ring material when selecting an O-ring for a particular application, as the material can have a significant impact on the squeeze experienced by the O-ring and the overall performance of the seal. By carefully selecting the right material for the application, engineers and technicians can ensure that the O-ring provides reliable and long-lasting sealing performance.

Summary

In conclusion, O-ring squeeze is a critical factor in the design and installation of O-rings in industrial machinery, as it affects the ability of the O-ring to form a tight and secure seal. By measuring and controlling the amount of squeeze experienced by the O-ring during installation, engineers and technicians can ensure that the O-ring provides reliable sealing performance.

Our O-ring squeeze calculator is a valuable tool that can assist in obtaining the squeeze percentage by calculating it based on the original cross-sectional diameter of the O-ring and the diameter of the O-ring after compression and installation in the gland. The calculator can provide valuable insights into the squeeze experienced by the O-ring, helping engineers and technicians to optimize their design and installation processes.

It is important to note that recommended squeeze ranges for static and dynamic applications can vary depending on the specific requirements of each application. Additionally, other factors such as temperature, pressure, and the materials used in the O-ring and gland can also affect the squeeze and overall performance of the O-ring. As such, it is essential to use a combination of tools, including the squeeze calculator, to ensure optimal O-ring performance.

By considering all of these factors and using the right tools, including the O-ring squeeze calculator, engineers and technicians can ensure that their O-rings are designed and installed correctly to provide reliable and effective seals in industrial machinery.