Reverse Engineering Services

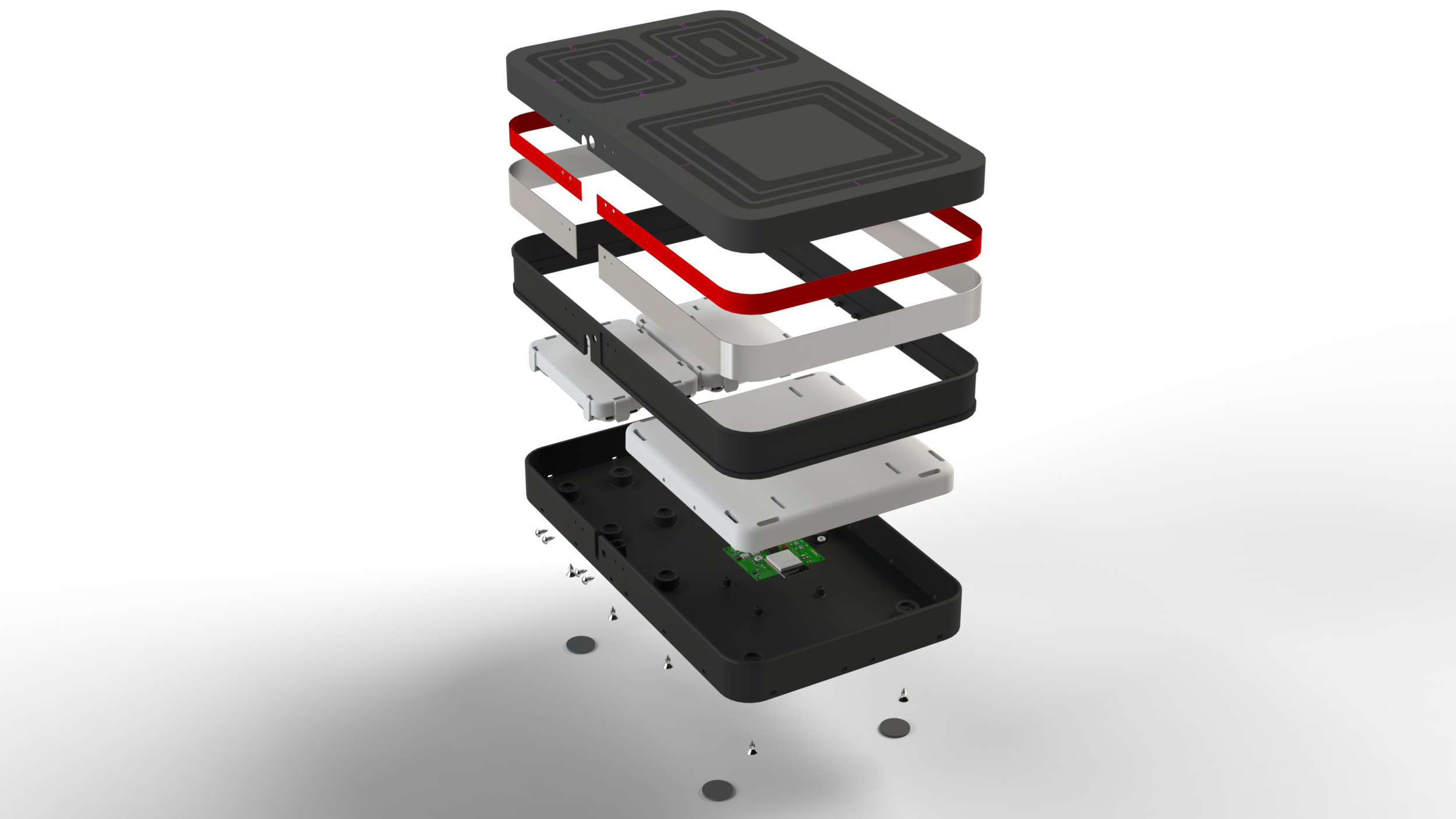

Unlock the full potential of existing products and components with our state-of-the-art Reverse Engineering services. By combining advanced 3D scanning, precise metrology, and comprehensive First Article Inspection (FAI & FAIR), we meticulously deconstruct, analyze, and recreate items to serve your current needs and future goals. From understanding competitor products to reviving legacy parts and enhancing design functionality for improved performance or manufacturability, our services are the bridge between the tangible and the digital, facilitating innovative solutions.

Benefits

Accuracy and Precision: Leverage advanced 3D scanning and metrology for highly accurate data capture and analysis, ensuring that every detail of the original product is meticulously reconstructed.

Insight and Innovation: Gain in-depth insights into the design, materials, and manufacturing processes of any product, enabling innovation and improvement in your own product designs.

Cost and Time Efficiency: Reduce development time and costs by utilizing existing designs as a foundation for enhancements, avoiding the need to start from scratch.

Flexibility and Customization: Adapt and customize products for new applications or technologies, with the flexibility to meet specific requirements or integrate with existing systems.

Quality Assurance: Through FAI & FAIR, ensure that all reconstructed designs meet stringent quality standards and specifications, ready for manufacturing or further development.

Our Process

Initial Consultation: We begin with a deep dive into your project objectives, whether it's competitive analysis, legacy part digitization, or design improvement, tailoring our approach to meet your goals.

3D Scanning and Metrology: Employing cutting-edge technology, we accurately capture the physical product's details, ensuring a comprehensive data set for reverse engineering.

First Article Inspection (FAI & FAIR): Conducting detailed inspections to verify that the product adheres to all specifications, understanding the product’s design intent, materials, and manufacturing process.

Data Analysis and Parametric Model Reconstruction: Our engineers analyze the captured data to reconstruct accurate parametric models, utilizing CMM critical dimensions to ensure fidelity and precision.

Design Enhancement and Customization: With the reconstructed model as a base, we explore design enhancements for better performance or manufacturability and customize the design for new applications as required.

Prototype and Validation: Prototypes are produced for physical testing and validation, confirming that the redesigned product meets or exceeds the original specifications and performance expectations.

Delivery and Support: The project culminates with the delivery of digital models, detailed project reports, and any prototypes, accompanied by ongoing support for further modifications or integration needs.

Discover the transformative potential of our Reverse Engineering services for your product development and manufacturing processes. Reach out today to begin exploring the possibilities together.

Learn how CADify helped our Client design a Teflon Face seal utilizing shrink fit FEA techniques.